Refurbishment of a CAM HV used cartoner

Mipco was chosen by a specialist in dietary supplements to refurbish a CAM HV used cartoner (year 2000). This equipment was taken from the Ingenneo’s stock.

For that same file, our customer also bought a CAM SMP case packer (year 2003). The whole set was installed in our workshop as it will be set up in the factory.

The case packer was also put to format, and we created ourselves the link-conveyor between the two machines.

The operation was realized in less than 10 weeks.

You are looking for a responsive company to settle all your technical issues ? Do business with us !

In details:

- The machines were prepared, and a first level maintenance was realized.

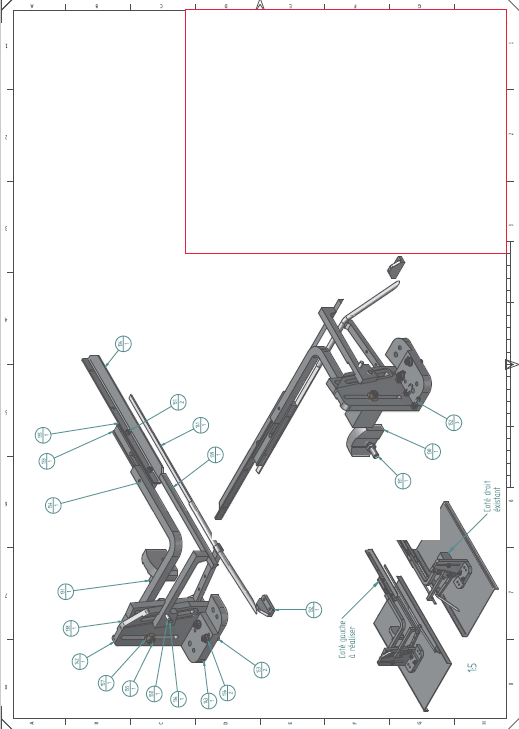

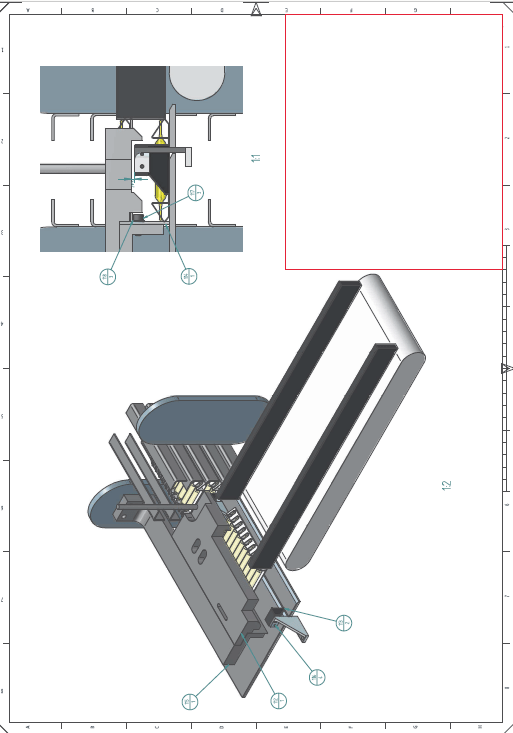

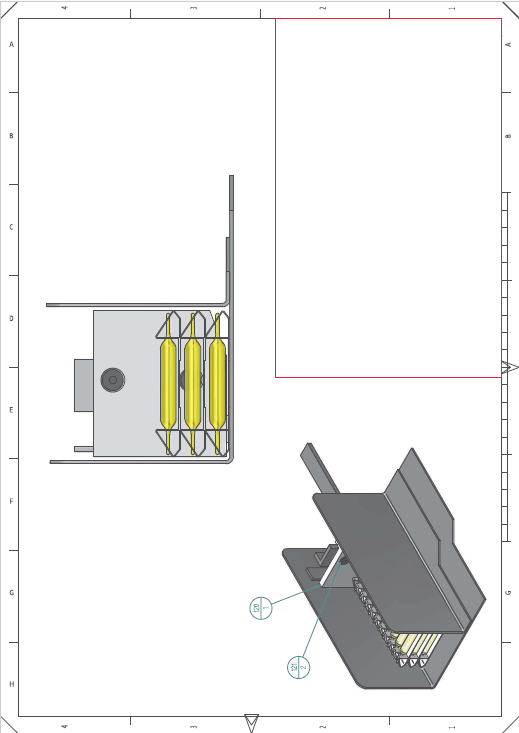

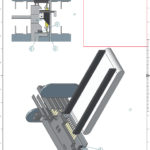

- The blister-bundling section was modified: mechanical study (nomenclature and 3D plans included) and modification of pieces.

- The accessory feeder and the notice feeder were disabled (useless for this application).

- The buckets’ chain was modified for the 3-blisters format: 48 buckets were dismantled/modified/reassembled.

- The cartons’ shaping device was adjusted.

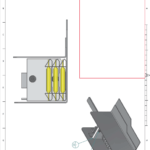

- The guides of the cartons’ closing flaps were entirely redrawn.

- The 12 pushers (whose function is to push the blisters in the cartons) were modified.

- A one-week intervention of an automation engineer was scheduled.

For information, we realized the same type of operation last year on used cartoners: