This small new company manufactures in small and medium production bio lipsticks of very high standard. Besides, they needed a pilot equipment, allowing the testing and the validation of the batches’ size in adequacy with their present or future references.

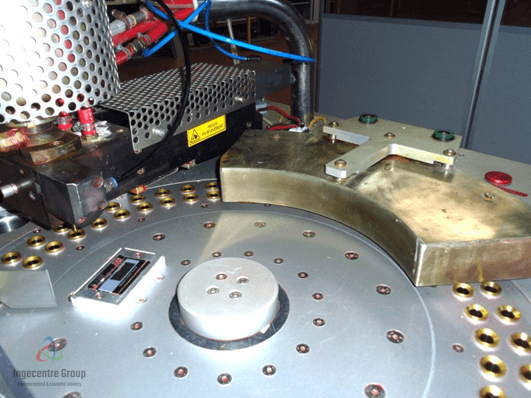

They chose a used semi-automatic WECKERLE filler, type W81, year 1994. Intended for the molding of lipsticks, this equipment fitted completely, having being used in similar conditions by a great industrial of luxury.

Because the equipment did not fit into safety norms for operators and for some electrical elements, the main aim of the project was to bring it to conformity. The equipment was first examined by an approved inspection agency, in order to list the points to correct.

- Complete casing of the working plan and of the prints’carrousel.

Integration of the doors’ opening control to the safety chain.

Repositioning of the control panel. - Disassembly and complete checking of the thermal fluids networks (hot water and cold water).

Replacement of the whole set of hoses of the thermal circuits by new material.

Checking of the temperature regulation organs. Replacement of the non-dependable elements. - Renovation of the hot product circuit and of the lubrication circuit of the prints.

Linking of the temperature-holding system and of the product hopper’s agitator to the opening of the door. - Refurbishment of the remelting-after-molding station.

- Integration of a pneumatic electrovalve to the emergency stop safety chain.

Setting ATM of the pneumatic networks of the emergency stop. - Leak test of the built-in refrigeration unit by an approved agency.

- Supplying and putting into operation of an external refrigeration unit.

- Checking and recovery of the electrical cabinet (arrangement of the cables, adding of the safety components and additional labelling).

Update of the pneumatic and electrical diagrams. - Factory Acceptance Test of the used filler. Installation on the production site.

Training of the operators for the use of the machine and format change. - Validation of the technical and safety improvements by an approved inspection agency.

- Realization of the technical documentation of the used filler, including: operator manual, safety instructions, diagrams, technical documentation of the components and related certificates…

The work realized on this used filler allowed this small company to perform its pilot tests, and to commercialize its very specific product with a moderate investment.