Our customer, an actor of the luxury cosmetics industry, owns a mixer manufactured by Moritz in 1992. Maintenance on the critical elements of this mixer had not been performed for years, and MIPCO was chosen for that task.

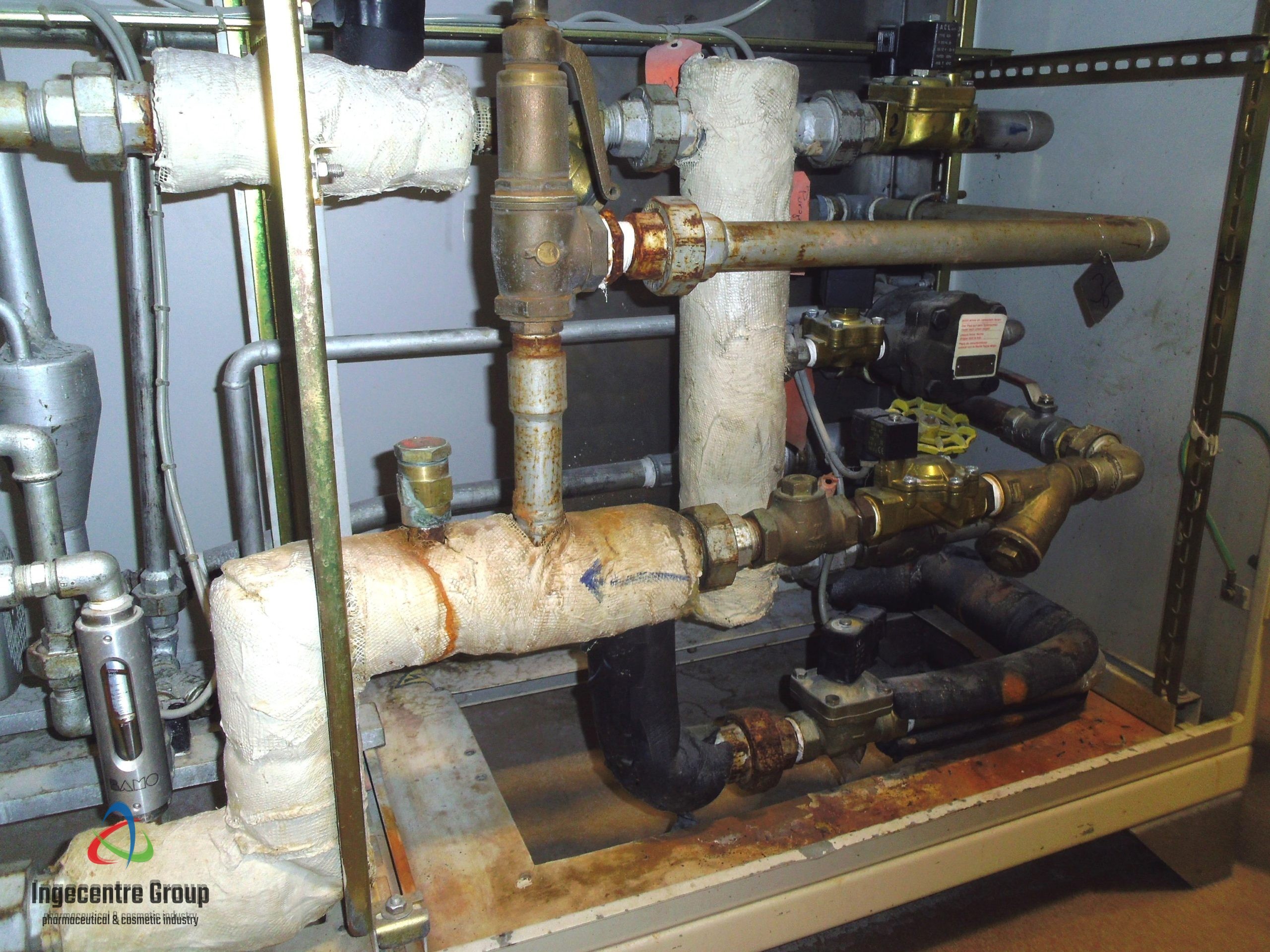

First part of the job was to replace all the fittings and elements of thermal circuits distribution used for heating/cooling during dispersion and mixing. Note : specifications did mention nor the replacement of the pipes neither the repair of insulation devices.

- Electrovalves of the steam circuit and cooling water circuit

- Filters, drainers and accessories

- Safety valve (protecting the double-jacket)

- Thermal fluids feeding hoses

- Tests before qualification

Second part of the job consisted in the refurbishment of the tank bottom disperser’s guiding shafts, and of the coaxial mixing tools mounted on the tank dome.

- Disassembly of the mechanical seals , and metrology of the guiding elements

- Replacement of the bearings, castle nuts, etc.

- Replacement of the installed graphite mechanical seal by ceramic seals, and replacement of the springs

- Replacement of all the seals

- Reassembly and adjustments

- Control of pressure and temperature conditions of the mechanical seals’ glycerin lubricating circuit

- Tests in working conditions before qualification.

The delivery included the updating of the nomenclatures with the new components.

After six months of operation, our customer has noticed nor dysfunction neither leak in the new configuration.