Our company is specialized in trading second-hand industrial equipment for the pharmaceutical and cosmetics industries. We ship worldwide, with 50% of our turnover in France, 25% in Europe and 25% for export.

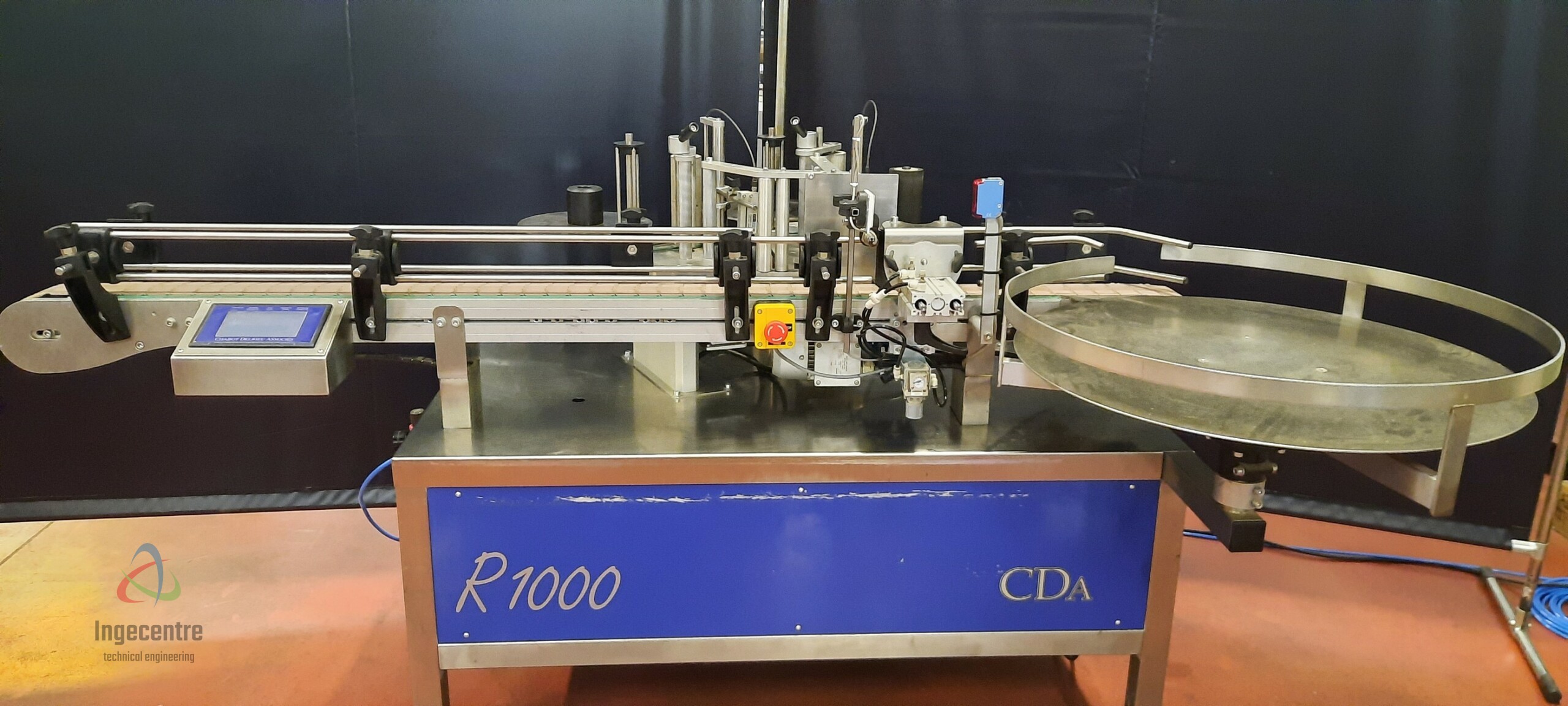

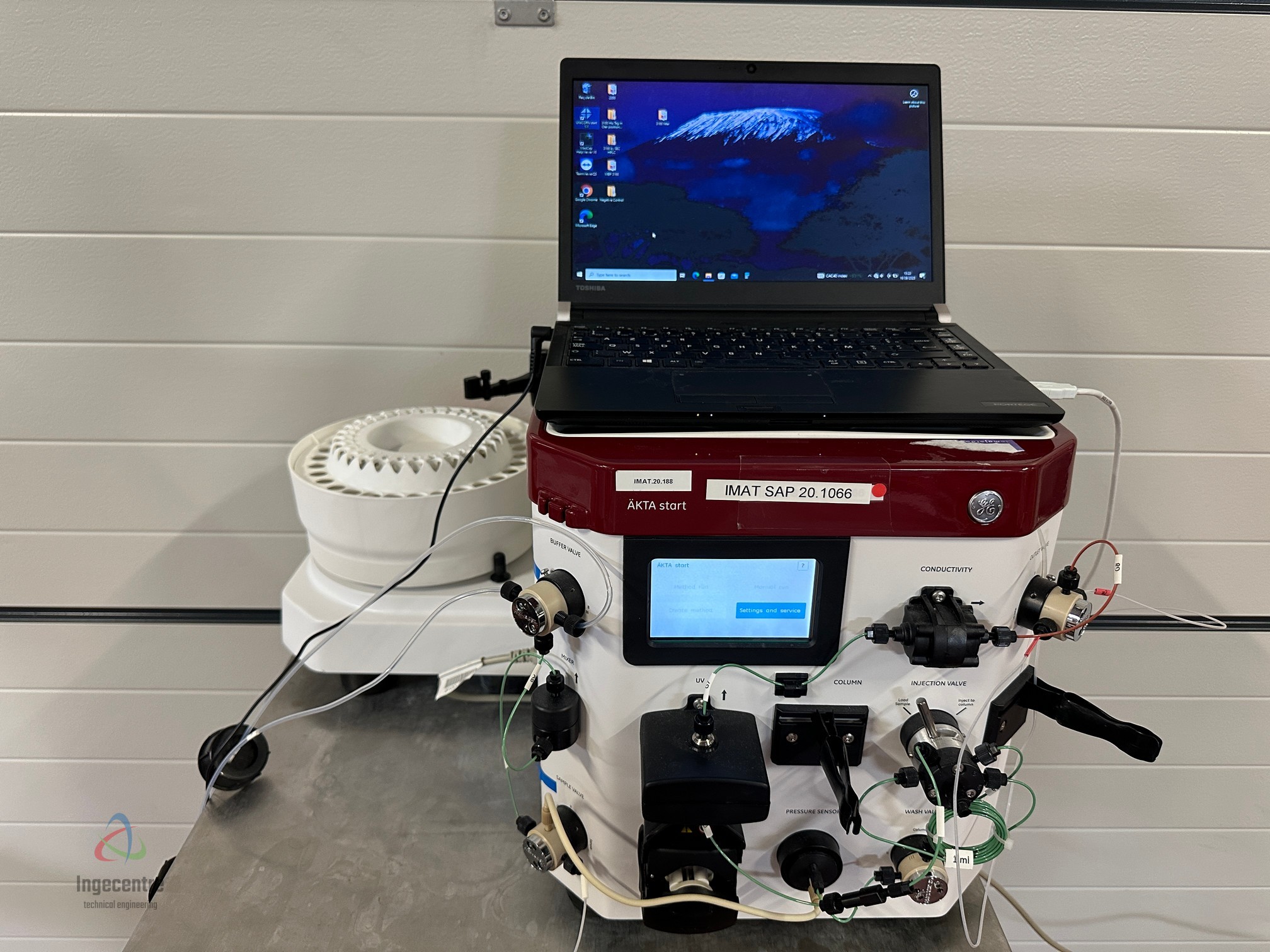

Our storage warehouses, with a capacity of 4000m², are located near Orléans. We have a large choice of process and packaging equipment (more than 500 machines in stock), tested and functional (to discover on our YouTube channel).

Our catalogue includes many references such as industrial ovens, labellers, filling machines or second hand laboratory equipment.

And we also buy back your second-hand equipment.

Our goal: to provide pharmaceutical and cosmetic equipment that meet our customers’ needs

Why choosing used equipment?

It’s a matter of efficiency: in terms of production, second-hand is quite at the level of new, but at a more reasonable cost.

- Environmental efficiency, with a reduced carbon print

- Financial efficiency, with reduced costs of investment

- Operational efficiency, with reduced delays

By the way, the second-hand market is very lively, and your solution exists, whatever your project is.

read more

By requesting the services of the leading company on the market of second-hand equipment for the pharmaceutical industry in France, you trust our technical knowledge and our experience on the machines.

Our process: understanding, identification, proposal

- We understand your need

- We identify the most accurate machine

- We make a proposal in accordance with your production imperatives

Then, inspect the machine! Two ways are possible:

- You come by our premises, where you will see the machine working « live »

- We send you a video of the machine running with your formats of products

Fewer useless complications: it is possible to consult us for the organization of the transport and the installation in your factory, so that you’re assured of the condition of the equipment delivered.

You are looking for a used equipment? Do not hesitate:

- To check our online catalogue

- To contact us directly

Our Mipco brand offers you its technical engineering services.

Our 450 m² maintenance workshop allows us to refurbish any of your production equipment.

Our preventive and corrective maintenance team includes technicians specialized in mechanics, electromechanics, electricity, automatism, robotics and handling, ready to intervene on all France.

Mipco supports you

- Refurbishment

- Putting to formats

- Realization of new conveyors

- Realization of casings

- Implementation of maintenance contract

- On-site intervention

- Intervention at our premises

- Machine compliance

- Automatism and robotics services

- Expertise in methods and organisation of maintenance trades

- Drafting of preventive maintenance ranges

- Drafting of procedures

- Realization of FAT, SAT and PRS

- Organization (planning)

- Provision of plans

- DOE

of the machines we have in stock

Mipco integrates robotics and automatism in your projects

Ingecentre now integrates a new pole of expertise: Automatism and Robotics, to strengthen our team and allow us to offer our customers an increasingly comprehensive and effective service.

Thanks to these new competences, we are in position to design, implement and optimize complex automated systems, thus meeting the most specific needs or our customers. Either be it to automate a production process, to improve the performance and safety of a machine, or to develop intelligent robots, we will bring you tailormade and innovative solutions.

read more

We are convinced that this additional knowledge is going to allow us to meet new challenges and to innovate more and more. We look forward to put these skills and our experience at your service, to support you in your digital transformation, and to achieve your goals of performance and competitiveness.

AUTOMATISM

- Most common PLC (Siemens, Schneider, Omron).

- Barcode readers, data matrix (Keyence).

- Vision sensors, shape/color/measure detectors (Keyence).

- Safety: Siemens safety automatons, Sick/Pilz programmable relays.

ROBOTICS

- Conventional: Fanuc (5,6 or 7 axes) ; we are trained in DCS programming (safety).

- Collaborative: UR (Universal Robot) ; our team has followed with this manufacturer an intensive training session, to embed new machines or perform maintenance operations.

Values and know-how

In-depth knowledge of equipment in the pharmaceutical industry

15 years of experience with major players in the pharmaceutical sector

Work smoothly with a reliable partner

A specialized, dynamic and responsive team

Working in transparency to ensure optimal results

They have placed their trust in us