Our customer works in contract packing in the high level cosmetics sector. In the context of series of lipstick cartoning, they chose a Marchesini MA 100 automated used cartoner (year 2004).

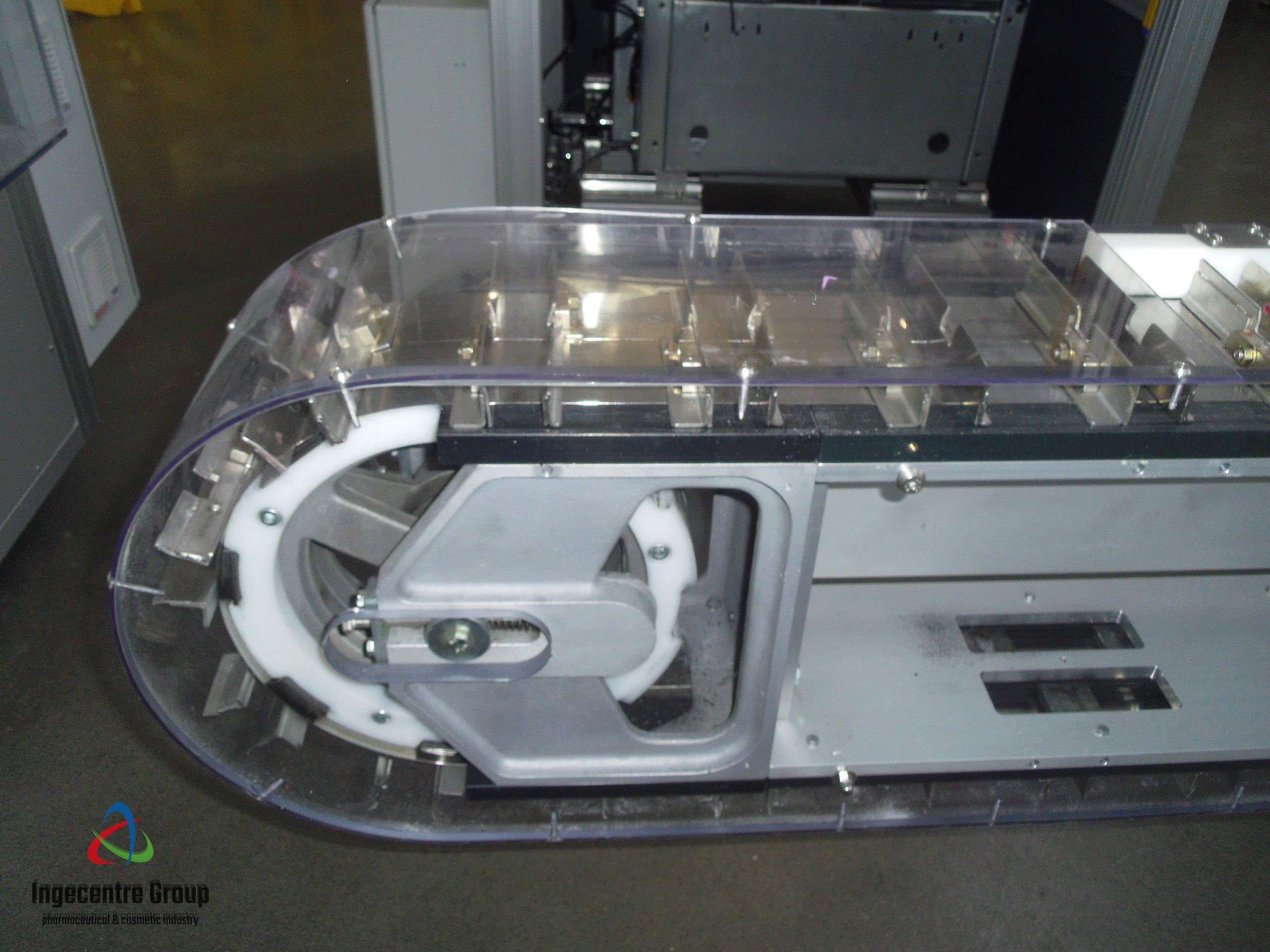

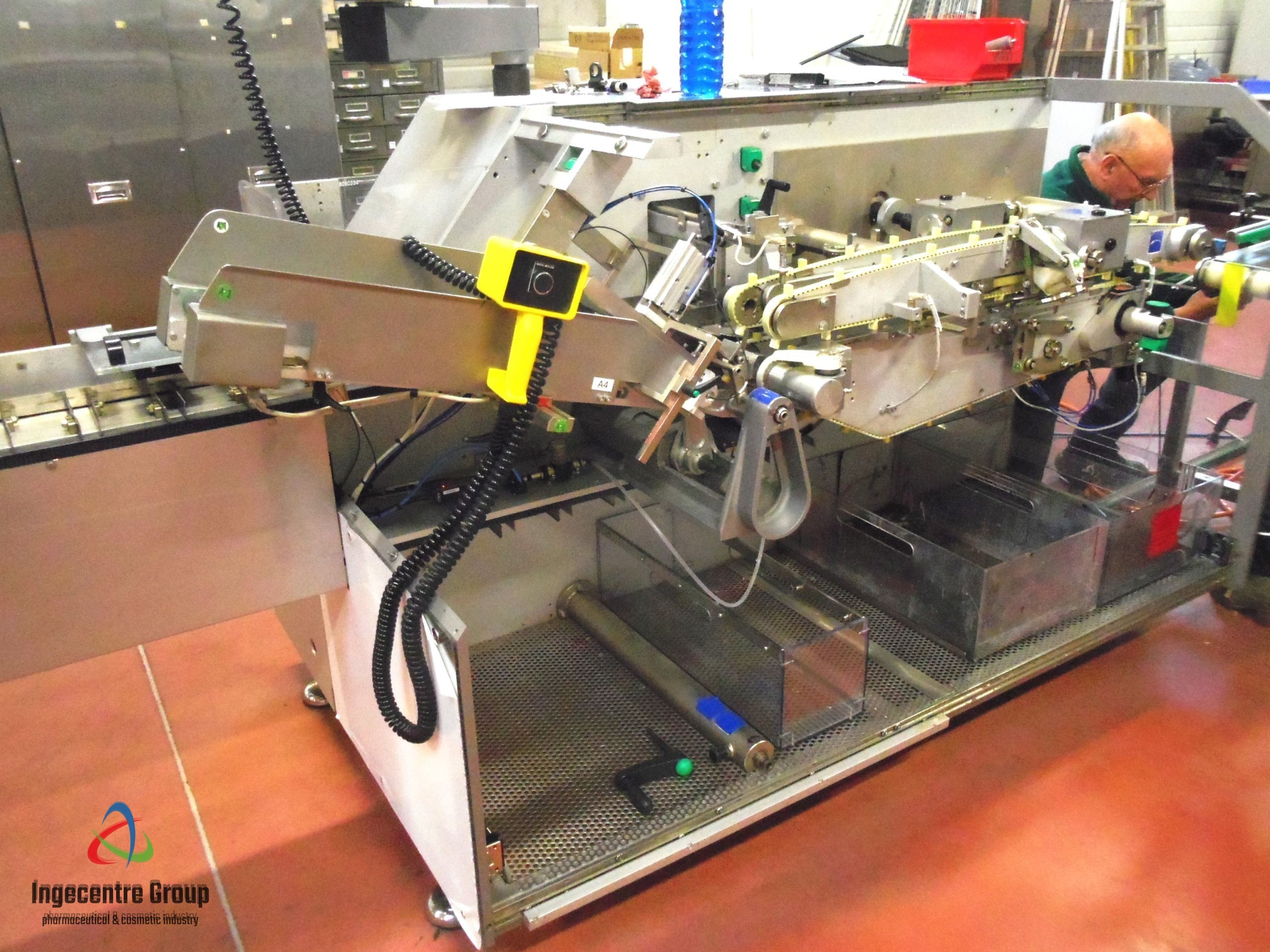

A first level maintenance was performed, mainly consisting in an inspection of the mechanical and transmission parts, and in the replacement of the stainless steel belt carrying the products towards the cartoning station.

The control system of this used cartoner was completely revised under the care of MIPCO. Thus, the former device was replaced by a new Siemens S7-300 PLC, linked to a Siemens 8” MP277 operator touch panel. All the control components (incremental encoder, safety chains of operator openings…) were updated or replaced. Wiring was also updated.

The study of theformat parts for the three cartons’ dimensions (29x28x80 mm, 27x26x115 mm and 28x28x79 mm, all with coplanar flaps) was realized under control of MIPCO. The critical quality constraints for the acceptance of that used cartoner were that no traces made by a point of support should be viewable (pushers or closing tools), and no friction scratches were allowed (guides…).

All the formats’ adjustments were performed by MIPCO technicians, closely with our customer’s production staff.

Finally, the deal concluded between MIPCO and its customer included the supply of a technical file taking into account the modifications and improvements carried out on this machine (operator manual, diagrams’ update, technical documentation of the installed components, adjustment sheets…), complementing the initial manufacturer’s documentation.

After this used cartoner was inserted in the line, a satisfaction survey was conducted, whose conclusions were that the functioning and performances met the requirements of the user.